Construction dewatering is not a “one-size-fits-all” problem. A low-horsepower wellpoint pump may be all that is required to get the most bang for your budget. MB Exports is the budget-friendly and the best Dewatering Pump Manufacturers in Australia. The Compact Rotary Pump has become a strong competitor to the traditional Piston Pump since its release in March 2020. The “Compact 6′” is particularly adaptable due to its smaller yet lighter design, high performance, quiet pack, and low fuel consumption. It has 16 fewer HP than the Standard 6, making it ideal for tiny wellpoint systems and shorter sock runs where larger units would be “overkill.”

Old Technology vs. High-Efficiency Agile Pumps

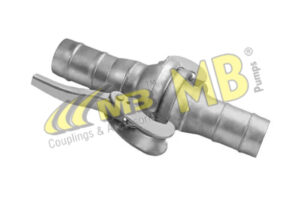

The more efficient and modern rotary wellpoint pumps predate piston pump technology. The Compact Rotoflo is a self-priming, rotary lobe, positive-displacement pump with no valves. It is specifically developed for construction dewatering and can easily pump slurries and brackish water. When combined with the horsepower required for smaller operations, the benefits in long-term ownership, maintenance, and performance are significant. Furthermore, the Compact RotofloTM’s ability to move around in tight places, along with a standard D.O.T. box for convenient transportation, makes this pump incredibly agile and a step above the competition.

Here are seven reasons why MB Exports Pumps’ Compact RotofloTM is the ideal solution for minor construction dewatering:

The Compact Rotoflo Competitive Advantage

- Smaller, Lighter Design: The Compact RotofloTM piston wellpoint pump is more than 30% smaller and lighter than comparable piston wellpoint pumps. Simply said, it fits in places where others do not. This makes it ideal for difficult water pumping difficulties in tiny residential communities and congested business districts with limited space.

- High Performance (425 GPM & 208’ TDH): The pump’s simple design avoids the need for sophisticated vacuum priming, floats, and inconsistent air/water separation systems.

- Low Maintenance: The maintenance-on-site concept significantly reduces downtime. Each pump includes a quick-release cover that may be removed with standard hand tools. This allows for easy access to the inner workings without the need to remove crucial components. Because of its 100% bolt-together design, numerous units can be readily coupled for maximum power.

- Lower Cost: With low maintenance and robust components, this pump is less expensive than comparable systems and can be set up and used in a fraction of the time.

- Quiet Pack Standard: This feature is suitable for residential or sensitive locations where noise levels must be minimal. The Compact RotofloTM is lined with 16-gauge steel and has sound insulation to achieve a noise level of 67dBA at 7M / 23′, giving it a distinct advantage over the piston pump.

- Low Fuel Consumption: The Compact RotofloTM, with a fuel capacity of 28 gallons, may run for up to five days, depending on the load. This reduced fuel usage gives the pump a significant advantage over inefficient piston pumps. The very efficient air/water management capabilities use less fuel while giving fewer difficulties, whether employing a wellpoint or sock system. This pump includes a Yanmar L100W Tier 4 Final engine as standard. The pump can be customized with a diesel, electric, or hydraulically-driven diesel engine with an optional variable frequency drive.

Additional Options and Benefits

While these are the main benefits of the Compact Rotoflo RWP006 Rotary Wellpoint Dewatering Pump, it also comes in skid or trailer-mounted versions. Other features include dry-running mechanical seals, a positive displacement tri-lobe spiral rotor, and the complete pump being built in Australia by MB Exports is your trusted Dewatering Pump Manufacturers & Suppliers in Australia.

Read more about THE DIFFERENCES BETWEEN CENTRIFUGAL AND POSITIVE DISPLACEMENT PUMPS.